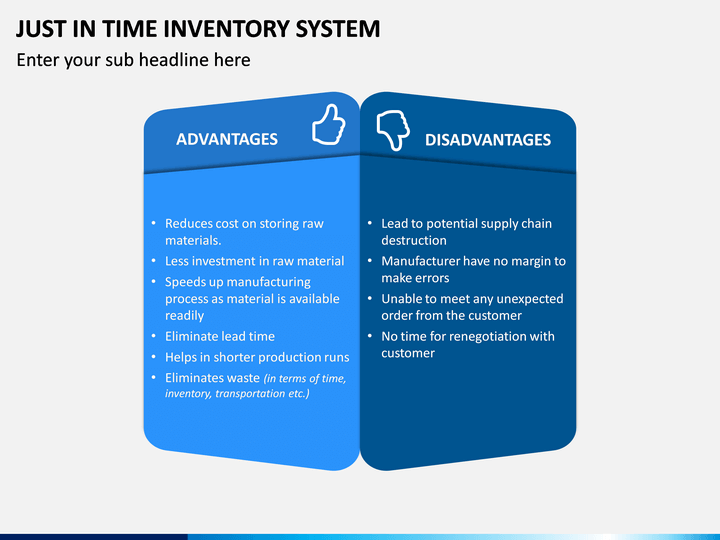

Further, the waste also includes storage, capital waste trapped in the unprocessed inventory, waste that transports the inventory, containers that possess inventory, and storage space lighting. This type of waste is referred to as waste that is produced via irregular inventory. Under Lean Manufacturing, seven types of wastes are currently identified, such as inventory, defects, waiting, over-processing, Transport, and overproduction. At the same time, it reduces the overall costs while enhancing revenue. It aims to integrate all the steps necessary to make production holistic, and completely efficient. By the looks of it, the removal of waste takes place right within the manufacturing system Lean is accountable for different types of waste such as continuous human motion. The process of eliminating waste through lean is called Muda.

What are the seven waste products in Lean Manufacturing?

#JUST IN TIME INVENTORY QUIZ QUESTIONS PROFESSIONAL#

If you want to enrich your career and become a Certified Lean Professional then enroll in Lean Training This course will help you to achieve excellence in this domain.Ģ.

Empower people and fellow employees in the company for building trust between the workforce and the management.The following are the crucial elements of Lean Manufacturing: What are the crucial elements of Lean Manufacturing? MindMajix offers Lean Interview Questions that help you in cracking your interview & acquire a dream career as a Quality Analyst.Īfter in-depth research, we found that these questions and answers can impress your potential employer. Moreover, professionals will find some of the most fundamental problems, whereas advanced level questions help them land the best job. In this article, we’ve compiled some of the most sought-after interview questions alongside answers. Lean management segregates the value by ultimately reducing everything and anything that doesn’t add value. However, the other side is increasing productivity. Reducing waste during production is one side of the coin. The methodology is ideal for manufacturing facilities that produce tons of products and reduce waste.

Without Toyota, Lean Manufacturing wouldn’t have seen the light of the day.

The core principles of Lean Manufacturing help businesses across the globe to become efficient to compete in any vertical. The production also comprises neglected resources that include everything ranging from manufacturing management tools to expert staff. The process oversees that all of the resources are deployed efficiently during stunt production. Lean manufacturing, also known as lean production, addresses the most indispensable part of manufacturing, i.e., waste.

0 kommentar(er)

0 kommentar(er)